Sugarcane Bagasse / Pulp

Sugarcane Bagasse / PulpSugarcane bagasse itself is a waste material, the dry fibrous residue left after sugarcane stalks have been

crushed to extract the juice mainly for sugar manufacturing. When the fibers already crushed, less energy is

required to make bagasse products compared with pulping wood for paper products.

Products made from sugarcane bagasse are strong and durable, natural fibre is very pleasant to touch and

breathable. Leak and oil proof, with no lining required. Microwavable (warm up only). Refrigerator safe.

Compostable and recyclable (paper stream)

Our products are made to decompose in a commercial composting facility within 60-90 days. Suitable for

home composting.

Bamboo / Pulp / Paper

Bamboo / Pulp / Paper

Fast growing bamboo regenerates quickly, making it a sustainable choice. Growing at a rate of up to 91 cm a

day, Bamboo is one of the fastest growing plants on earth. Bamboo requires no irrigation and unlike trees it

rarely needs replanting after it harvested, it grows rapidly and can be harvested in 3-5 years.

Wood / Paper

Wood / Paper

The original raw material used for our wooden cutlery and paper cups manufacture is wood fibre, from sus-

tainably managed forests, natural renewable resource.

Paper cups end of life options: our paper cups are lined with PLA lining and are compostable in industrial

composting facility only.

Wooden cutlery end of life options: compostable

Cardboard / Recycled contentCardboard is made from a renewable resource, compostable and easily recyclable, with less production emis-

sions.

The original raw material used for carton manufacture is wood fibre. At the end of life, cartons are collected

and recycled and form a secondary raw material.

End of life options

Folding cartons can easily be recycled by reprocessing in a mill, where the fibres are separated. The recovered

fibre is then used to make cartonboard or another paper or board product. Alternatively, they can either be

composted, a process also known as “organic recycling”, or if recycling is no longer a viable option, their en-

ergy content can be recovered in an energy-from-waste incinerator.

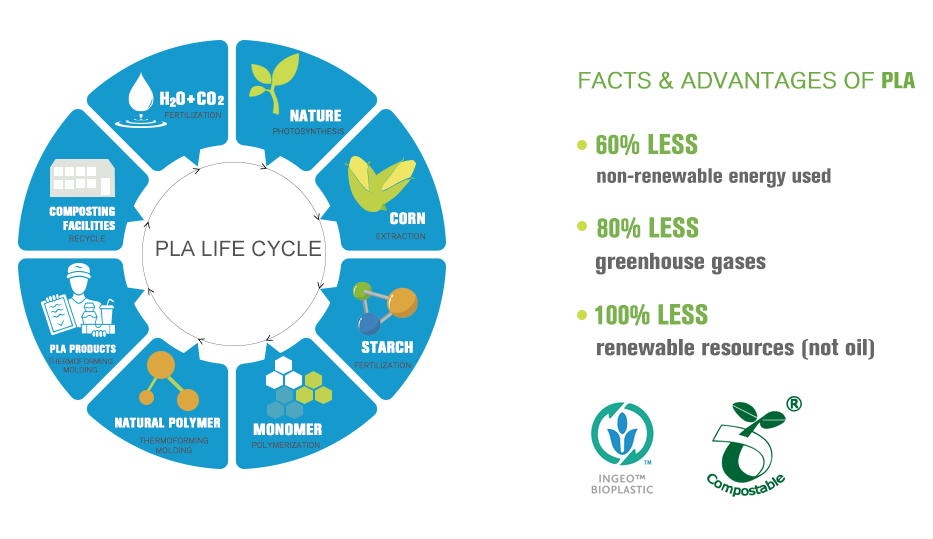

PLA Biobased Plastic

PLA Biobased Plastic

PLA biobased plastic is a bioplastic produced from corn. The production of PLA produces fewer greenhouse

gas emissions, when compared to conventional plastic production.

Products made from PLA bioplastic are compostable in industrial composting facility only.

Please note, that clear cups and containers are heat sensitive and must be stored out of direct sun, away from

any heat sources and kept below 35°C.

WHAT IS PLA (POLYACTIDE)?

Polylactic acid (PLA) is a thermoplastic derived from renewable resources. Common renewable resources used include

corn starch, tapioca roots, or sugarcane. PLA is compostable where facilities exist.

Carton Board

Carton board is made of pure wood pulp, unbleached or bleached with a typical surface weight exceeding 170 gr.

Advantage:

Fast and cost effective manufacturing, good for printing, smell and taste-free.

Temperature:

-20° to +70°. Not suitable for microwave heating.

Environment:

Manufactured from renewable raw materials.

Can be garbage-sorted and is bio-degradable.

Easy to recycle and can be used for energy production.

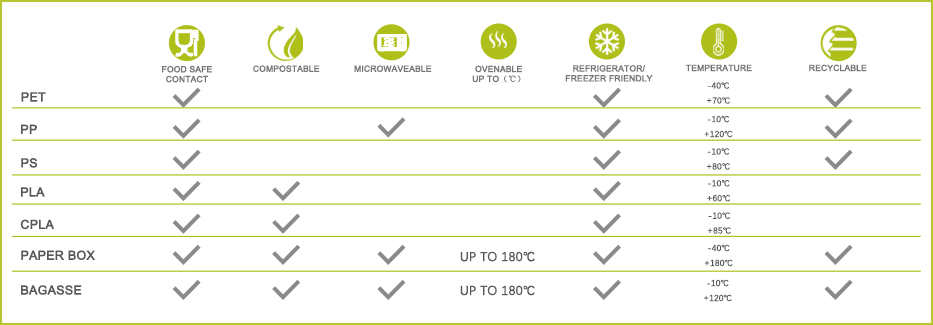

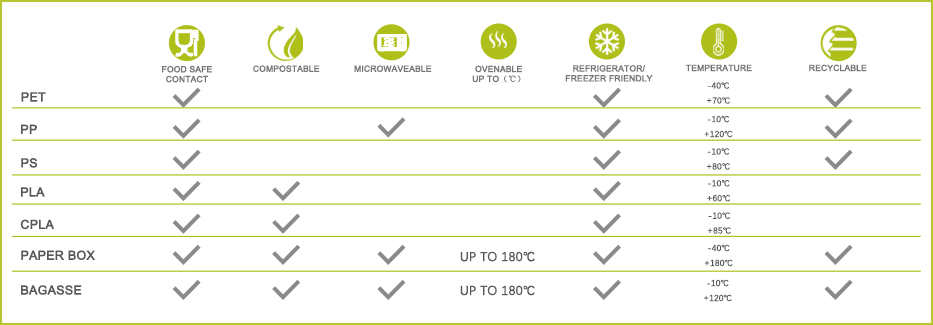

PET - Polyethylene terephthalate

PET - Polyethylene terephthalate

PET provides glass quality clarity and is used for consumer packages such as cups, containers, lids etc.

Advantage:

High durability, good strength and wearing qualities with extremely effective barrier against oxygen,water and acid.

Temperature:

-40° to +70°. Not suitable for heating in microwave.

Environment:

Fulfils the demands for environmental marking. Can be garbage-sorted and recycled.

Combustion gives almost as much energy as fuel oil. On combustion carbon dioxide and water are produced.

PLA - Polylactide

PLA - Polylactide

PLA is made from annually renewable resources such as corn and other agriculture crops, and thermoform with latest technology for consumable packages such as cups, trays, food containers etc.

Advantage:

Reduce CO2 emission, fully compostable, visual appealing, strong, durable, superior flavor and aroma barrier.

Temperature:

0° to +45°. PLA is highly sensitive, heat-liner is suggested for shipment which could be re-usable in warehouse.

Environment:

Fully compostable in municipal or industrial facilities.

Material can be disposed by all traditional methods such as incineration, landfill or mechanical recycling.

PP - Polypropylene

PP - Polypropylene

PP is used for packages, injection-mould boxes, warm formed drinking-cups, toys etc. Co-PP is tough and opaque while Ho-PP is more stiff and clear.

Advantage:

Good barrier qualities against moisture, high durability, excellent welding qualities.

Temperature:

-40° (co-polymer) or +2° (homo-polymer) to +121°. The material can be used in the microwave.

Environment:

Fulfils the demands for environmental marking. Can be garbage-sorted and recycled.

Combustion gives almost as much energy as fuel oil. On combustion carbon dioxide and water are produced.

PS - Polystyrene

PS - Polystyrene

PS is used for disposables, packages, household products, cutlery etc.

Advantage:

Clear, high luster, stiffly, smell/taste free.

Temperature:

-40° to +80°. Not suitable for heating in microwave.

Environment:

Fulfils the demands for environmental marking. Can be garbage-sorted and recycled.

Combustion gives almost as much energy as fuel oil. On burning carbon dioxide and water are produced.